Modern flashlights are used in a multitude of professional situations. Different working environments can pose hazards, such as a potential for explosion or fire hazards. Flashlights come in various forms, prompting the National Electric Code (NEC) to create safety classifications for the different kinds of flashlight technologies available.

Any flashlight that could be potentially used in a dangerous situation or confined space should be adequately tested to meet or exceed all applicable safety standards for those locations. When choosing a flashlight, make sure it carries the appropriate approval ratings. Choosing the correct light for your application requires a careful knowledge of your working environment, and a accurate anticipation of how a suitably selected flashlight will function in those surroundings.

Industrial, marine, public safety and military organizations develop specifications for flashlights for specialized roles. Typically light output, overall dimensions, battery compatibility and durability are required to meet minimum limits. Flashlights may be tested for impact resistance, water and chemical resistance, and for the life span of the control switch. Flashlights intended for use in hazardous areas with flammable gas are tested for external temperature, and are tested to ensure they cannot set off an explosion. In the United States, ANSI has developed standard FL1 which standardizes the test procedures for light output, impact and water resistance, and battery running time.

Defining a Dangerous Location?

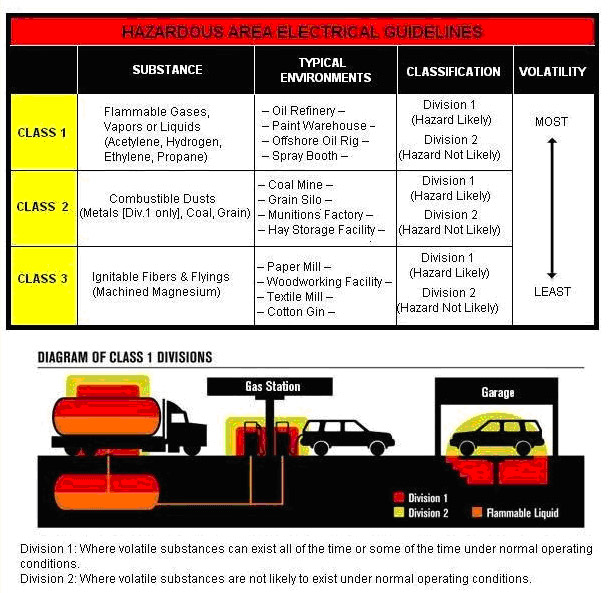

Flashlight technology has evolved to address specific needs and conditions of particular circumstances. Hazardous locations, or potentially explosive atmospheres, are areas where fire or explosion hazards may exist due to the presence of ignitable concentrations of flammable gases, liquids, vapors, dusts or ignitable fibers or flying debris. These locations are classified or “grouped’ according to the properties of the flammable materials that may be present and the likelihood of flammable concentrations.

The basic designation is by “class” and “division.” There are three classes characterized by the type of material present.

Class I locations are made hazardous by the presence of flammable gases, liquids or vapors.

Class II locations can be described as hazardous because of the presence of combustible dusts.

Class III locations contain easily ignitable fibers or flyings. “Division” refers to the likelihood that ignitable concentrations of flammable materials are present in a given area.

Division 1 designates an environment where ignitable concentrations of flammable gases, liquids, vapors or dusts can exist some of the time or all of the time under normal operating conditions or where easily ignitable fibers and fly-aways are manufactured, handled or used.

Division 2 locations are areas where ignitable concentrations are NOT likely to exist under normal operating conditions or where Class III materials are stored or handled.

Group A Acetylene

Group B Hydrogen

Group C Ethylene, carbon monoxide

Group D Propane, gasoline, naphtha, benzene, butane, ethyl alcohol, acetone, methane

Group E Metals including aluminum, magnesium (Div. 1 only)

Group F Carbonaceous dusts including coal, carbon black, and coke

Group G Dusts not included in E and F including wood, plastics, flour, starch or grain dusts